摘要:在现代应用中,密封条扮演着至关重要的角色。它们不仅用于填补缝隙,防止液体或气体泄漏,还具备增强结构稳定性和提高能效的功能。随着科技的进步,密封条的应用范围日益广泛,包括汽车、建筑、电子设备等领域。其重要性在于确保产品的性能、安全和耐用性,成为现代制造业不可或缺的一部分。

In various industries, sealing strips have become an indispensable component, playing a pivotal role in ensuring the efficiency and longevity of systems and products. These versatile components are often overlooked, yet their significance cannot be denied, especially in light of their wide range of applications across different sectors.

Sealing strips are essentially long, thin, and often flexible materials designed to create a barrier or seal between two surfaces or components. They are made from various materials like rubber, plastic, or metal, depending on the specific application and requirements. Their primary function is to prevent leakage of liquids, gases, dust, or any other foreign particles into a system or product.

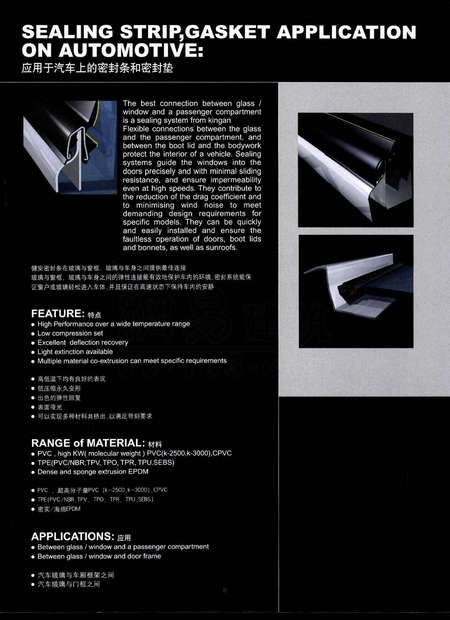

In the automotive industry, sealing strips are extensively used in various components like doors, windows, and engine compartments. They ensure that the vehicle remains protected from external elements like water, dust, and debris, thereby extending the lifespan of the vehicle and its components. The rubber or plastic material used in these sealing strips provides flexibility and durability, allowing them to withstand the rigors of daily use.

Moreover, sealing strips are also used in construction to prevent leakage in plumbing systems, windows, and doors. In this context, they play a crucial role in ensuring energy efficiency and maintaining a comfortable indoor environment. By preventing leakage of water and air, sealing strips contribute to reducing energy loss and improving the overall performance of buildings.

The electronics industry also heavily relies on sealing strips to ensure the integrity of products. In electronic devices like laptops, smartphones, and tablets, sealing strips are used to protect sensitive components from dust and moisture. They provide a barrier against external elements that can cause damage or malfunctioning of the device. Additionally, sealing strips are also used in solar panels to ensure the efficient transfer of solar energy to the panel's cells.

The packaging industry also utilizes sealing strips extensively. They are used to seal packages and ensure that the contents remain protected from external elements like moisture and dust. This ensures the integrity of the product and its shelf life. The use of sealing strips in packaging also enhances the overall appearance of the product and provides a secure means of packaging.

Moreover, sealing strips are also used in various other applications like agriculture, aerospace, and marine industries. In agriculture, they are used to protect irrigation systems and ensure efficient water distribution to crops. In aerospace, they are used in aircraft components to prevent leakage of gases and liquids, ensuring the safety of the passengers and crew. In marine applications, sealing strips are used in boats and ships to prevent leakage of water into critical components.

In conclusion, sealing strips have become an integral part of modern applications across different industries. Their versatility and reliability make them a crucial component in ensuring the efficiency and longevity of systems and products. With the continuous evolution of technology and advancements in material science, we can expect further advancements in sealing strips that will enable them to cater to a wider range of applications. As such, sealing strips will continue to play a pivotal role in various industries for years to come.