摘要:本文简要介绍了电镀工艺。电镀是一种金属表面处理过程,通过在电解质溶液中施加电流,使金属离子沉积在基材表面形成涂层。电镀工艺广泛应用于制造、汽车、航空等领域,以提高零件表面的耐磨性、耐腐蚀性和美观性。本文深入探讨了电镀过程的原理、应用及重要性。

Electroplating is a process of depositing a thin layer of metal onto a surface using an electrochemical process. This technique has numerous applications in various industries such as automotive, aerospace, electronics, and medical. The process involves several stages that ensure the quality and durability of the coating. Here is an insight into the electroplating process.

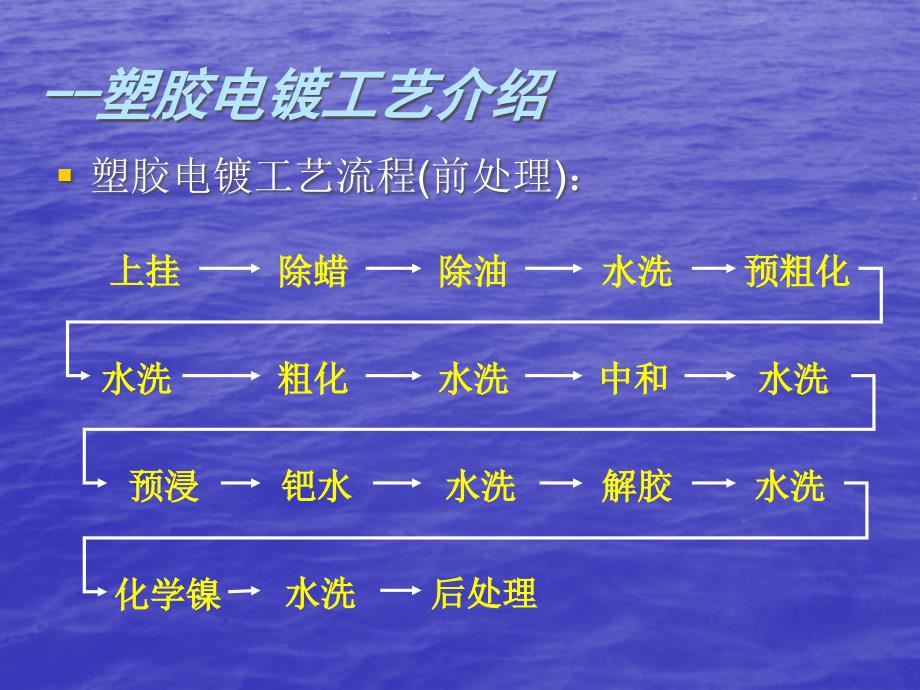

1、Surface Preparation

The first step in the electroplating process is surface preparation. It involves cleaning and activating the substrate to ensure proper adhesion of the coating. The substrate, which is the material to be plated, must be free from contamination, rust, or any other impurities. This is achieved through various methods such as mechanical polishing, chemical cleaning, and pickling.

2、Activation

After cleaning, the surface is activated to create a catalytic site for the deposition of the metal coating. Activation may involve the use of chemicals or a spark to generate a conductive path for the metal ions to adhere to the substrate.

3、Electroplating Solution

The next step is to prepare the electroplating solution, which contains the metal ions to be deposited on the substrate. The solution is made up of a mixture of salts, acids, and additives that help control the deposition rate and properties of the coating. The type of solution used depends on the desired metal coating (e.g., gold, silver, nickel, etc.).

4、Electroplating Process

In this stage, the substrate is submerged into the electroplating solution and an electrical current is passed through it. The substrate becomes the cathode (negative electrode) while the metal coating acts as the anode (positive electrode). The electrical current attracts the metal ions from the solution and deposits them onto the substrate, forming a thin layer of metal coating.

5、Control of Parameters

During the electroplating process, several parameters such as current density, temperature, and pH are controlled to ensure the quality of the coating. The current density affects the deposition rate and the thickness of the coating while temperature and pH influence the chemical reactions taking place in the solution.

6、Post-treatment

After the electroplating process, post-treatment steps are carried out to enhance the properties of the coating and improve its appearance. These include rinsing, drying, and heat treatment. Rinsing removes any residual solution on the coating while drying ensures that no moisture remains on the surface. Heat treatment may be applied to improve the adhesion and mechanical properties of the coating.

7、Quality Inspection

Finally, quality inspection is conducted to ensure that the electroplated surface meets the specified requirements. This involves visual inspection, thickness measurement, and testing for adhesion and corrosion resistance. The quality of the coating is crucial for ensuring durability and performance in various applications.

In conclusion, electroplating is a complex process that involves multiple stages from surface preparation to quality inspection. Proper control of parameters and adherence to best practices ensure that high-quality coatings are achieved. The electroplating process has numerous applications in various industries and plays a vital role in improving the performance and durability of materials.